Increasing Strength and Reliability of Interference Fits, 2013-10-01, Assembly Magazine

Por um escritor misterioso

Descrição

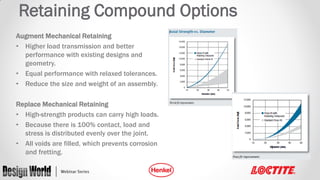

Interference fits, commonly referred to as press fits and shrink fits, are traditional methods for joining cylindrical parts. In an interference fit, the inner part—such as a shaft, bearing or bushing—is machined to be bigger than the mating hole of the outer part—such as a gear or housing. The larger part is then forced into the smaller part. Both parts deform slightly to fit together and extremely high friction results between them. The friction is so great that even large amounts of torque cannot separate . . .

Interference fits, commonly referred to as press fits and shrink fits, are traditional methods for joining cylindrical parts.

Diver magazine by The Special One - Issuu

Prediction of stress distribution in press-fit process of interference fit with a new theoretical model - Xingyuan Wang, Zhifeng Lou, Xiaodong Wang, Xiupeng Hao, Yue Wang, 2019

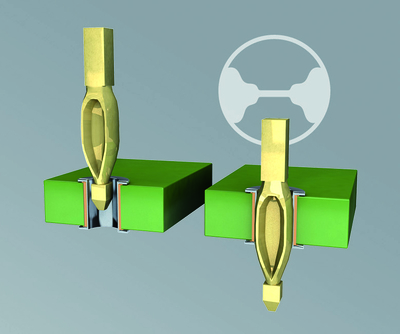

How to Install Threaded Inserts, 2013-10-01, Assembly Magazine

Increasing the Strength and Reliability of Press Fits

Machines, Free Full-Text

US7310544B2 - Methods and systems for inserting a transcutaneous analyte sensor - Google Patents

Torque capacity of the multilayer interference fit based on a friction coefficient prediction model - Ke Ning, Jianmei Wang, Dan Xiang, Dingbang Hou, 2022

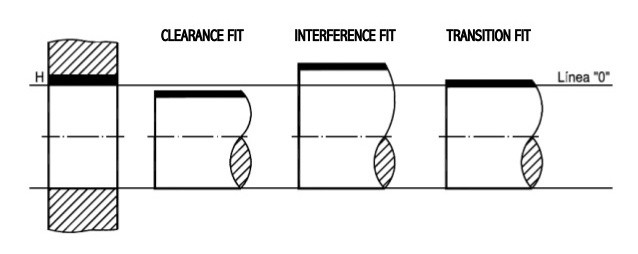

Interference fit geometry prior to assembly

US7310544B2 - Methods and systems for inserting a transcutaneous analyte sensor - Google Patents

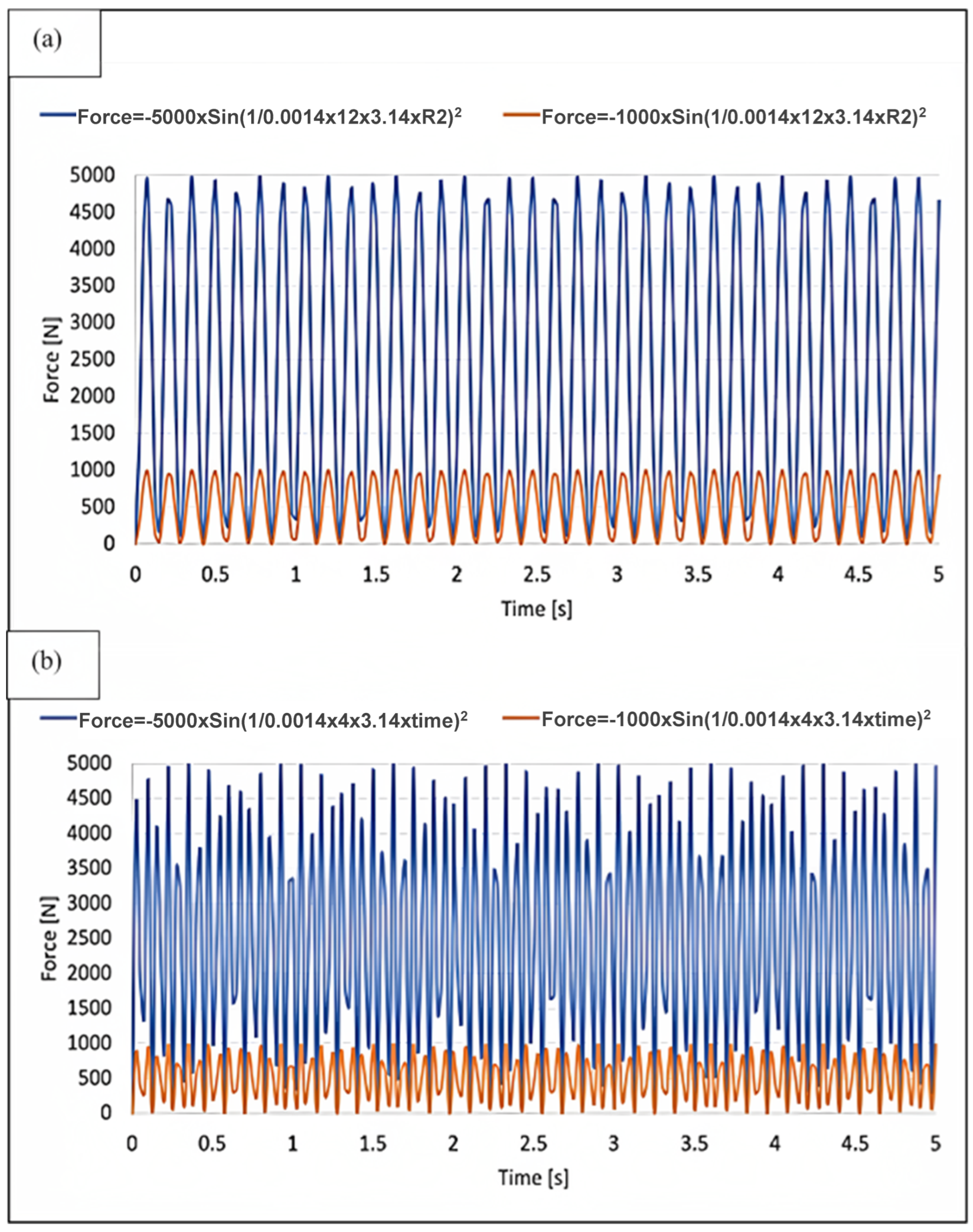

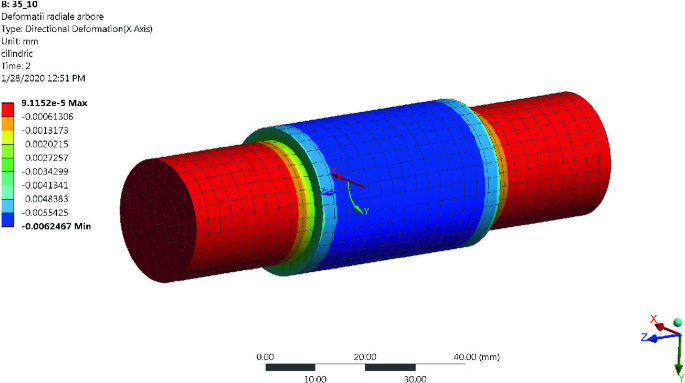

Interference Fits. Bearing Capacity Under Complex Loading – FEM Analysis

Analysis of increasing torque with recurrent slip in interference-fits - ScienceDirect

Interference Fit - an overview

Increasing the Strength and Reliability of Press Fits

Interference Fit - an overview

US8721545B2 - Transcutaneous analyte sensor - Google Patents

de

por adulto (o preço varia de acordo com o tamanho do grupo)

:max_bytes(150000):strip_icc()/_hero_horiz_Assassins-Creed-Valhalla-1-690610f1648e4765aa46b6f390d04c2f.jpg)